Glass setting materials are vital across sectors like automotive and construction, offering structural support and aesthetic enhancement. Environmental compliance standards guide their manufacturing and installation, focusing on energy efficiency, pollution control, waste management, and recycling. Choosing eco-friendly options, with recycled content or biodegradable alternatives, is crucial for reducing the environmental impact of auto glass services while meeting regulations. Industry professionals play a key role in promoting sustainability by adopting best practices that contribute to a greener future.

Glass setting materials play a crucial role in construction and design, offering both structural support and aesthetic appeal. From traditional sand and cement to innovative composite resins, understanding these materials is key to sustainable building practices. This article explores various types of glass setting materials, delves into strict environmental compliance standards governing their manufacture and installation, and highlights best practices for eco-friendly alternatives and responsible disposal methods.

- Understanding Glass Setting Materials: Types and Applications

- Environmental Compliance Standards for Glass Manufacturing and Installation

- Best Practices for Eco-Friendly Glass Setting Materials and Sustainable Disposal Methods

Understanding Glass Setting Materials: Types and Applications

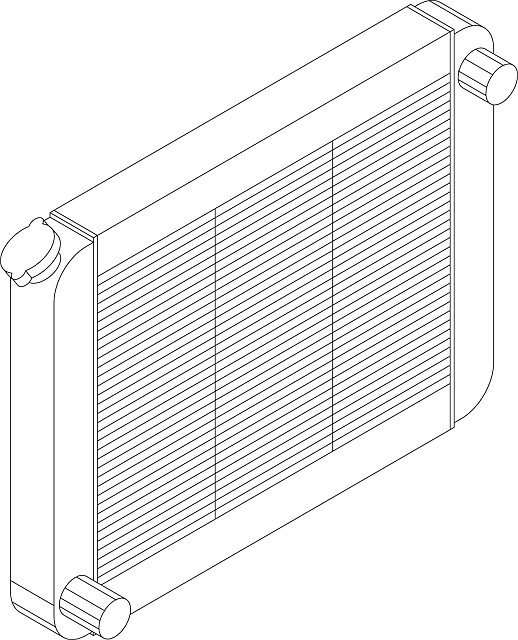

Glass setting materials play a pivotal role in various industries, offering both structural integrity and aesthetic appeal. These materials are essentially used to attach glass to different surfaces, ensuring it remains securely in place. The types of glass setting materials vary widely depending on the specific application. For instance, in the automotive collision repair sector, specialized adhesives and sealants are employed to fix windshields and side windows, requiring precise application to withstand high speeds and forces during driving. In contrast, tire services and body shop services often use different formulations tailored for bonding glass in more controlled settings.

Each type of glass setting material is designed with unique properties to cater to specific needs. For example, some are resistant to extreme temperatures, ideal for applications near engines or in exterior environments exposed to varying climate conditions. Others offer exceptional clarity and durability, crucial for architectural projects aiming to maximize natural light while ensuring structural stability. Understanding these materials and their applications is essential for professionals in the automotive, construction, and other related industries to meet environmental compliance standards effectively.

Environmental Compliance Standards for Glass Manufacturing and Installation

In the realm of glass setting materials, environmental compliance standards play a pivotal role in ensuring sustainable and responsible manufacturing practices. These regulations are designed to minimize the ecological impact of producing and installing glass, addressing various aspects from raw material extraction to waste management. The industry must adhere to stringent guidelines to prevent water pollution, control air emissions, and manage hazardous substances effectively.

One key area is managing the environmental impact of glass manufacturing processes. This includes implementing efficient energy usage, reducing greenhouse gas emissions, and minimizing dust generation during production. Additionally, proper disposal and recycling of glass waste are essential practices that contribute to a circular economy. Moreover, when it comes to installation, ensuring compliance involves following safety standards for vehicle repair services, especially in collision repair shops where precision frame straightening is crucial, while also adhering to local environmental regulations regarding construction and debris management.

Best Practices for Eco-Friendly Glass Setting Materials and Sustainable Disposal Methods

The selection and proper utilization of eco-friendly glass setting materials are pivotal steps in minimizing the environmental impact of automotive aftermarket services, including auto glass repair and dent removal. Industry professionals should strive to incorporate sustainable alternatives that not only meet performance standards but also align with stringent environmental compliance regulations. Best practices involve opting for recycled content, considering biodegradable options, and ensuring proper disposal methods that prevent harmful waste generation.

Implementing sustainable disposal methods is equally crucial. Instead of traditional landfilling, businesses offering collision repair services should explore recycling programs tailored to automotive glass. This not only conserves resources but also reduces the carbon footprint associated with production and disposal. By adopting these best practices, auto glass industry stakeholders contribute to a greener future while meeting the growing demand for environmentally conscious glass setting materials.

In conclusion, understanding the diverse range of glass setting materials and their applications is key to navigating the industry. Adhering to stringent environmental compliance standards in manufacturing and installation ensures a sustainable future. By adopting best practices for eco-friendly materials and implementing sustainable disposal methods, the industry can minimize its ecological footprint, contributing to a greener world while meeting the demands of modern construction projects.